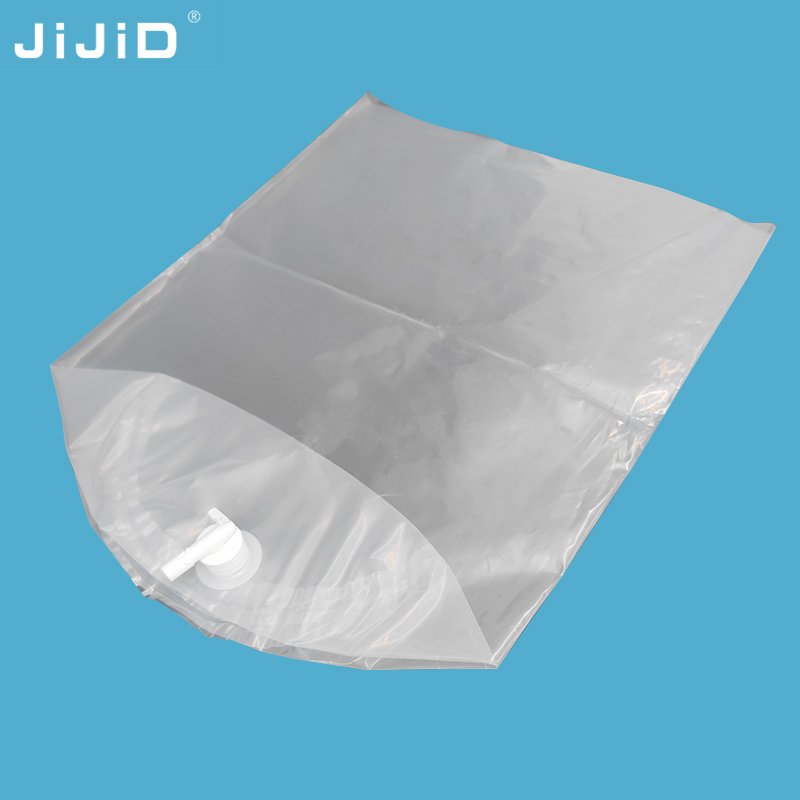

Round bottom liner bag is the perfect solution for drum lining applications in food, Chemikalie, or industrial industries. Designed to fit snugly into cylindrical containers, this liner minimizes waste and enhances hygiene.

Bestellleitfaden / So passen Sie Ihre Rundbodenbeutel individuell an

Um Ihnen genaue Vorschläge und Preise zu unterbreiten, Wir bitten Sie um die folgenden Informationen:

1️⃣ Materialpräferenz

Abhängig von Ihrer Anwendung bieten wir verschiedene Materialoptionen an:

-

Klares LDPE (Polyethylen niedriger Dichte)

– Standard oder antistatisch

– Sparsam, flexibel, und für den allgemeinen Gebrauch geeignet

– Ideal für Fülltemperaturen von 60–80°C -

Klar NY/PE (Nylon/Polyethylen)

– Lebensmittelecht, höhere Durchstoßfestigkeit

– Geeignet für Flüssigkeiten, Lebensmittelverarbeitung, und Chemikalien -

Aluminiumfolie (Hochbarrierefolie)

– PET/AL/PA/PE: Für normale Temperaturen

– PA/AL/PA/PP: Für Hochtemperaturabfüllung bis 165° C

– Vakuumierbar; Perfekt für eine lange Haltbarkeit, Barriereschutz, und pasteurisierter Inhalt

🔧 Wenn Sie unsicher sind, Wir können Ihnen dabei helfen, das richtige Material für Ihren Anwendungsfall auszuwählen.

2️⃣ Trommelabmessungen oder Beutelgröße

-

Bitte geben Sie Ihre an Trommeldurchmesser und -höhe, oder

-

Dein Außendurchmesser und Höhe des vorhandenen Linerbeutels als Referenz.

Dies hilft uns, den Liner so anzupassen, dass er eng anliegt, faltenfreier Sitz in Ihren Fässern oder Behältern.

3️⃣ Fülltemperatur

-

Was ist die maximale Temperatur der Flüssigkeit, die Sie in die Beutel füllen??

Dies ist entscheidend für die Wahl des richtigen Materials und der richtigen Versiegelungsmethode.

-

≤80°C → LDPE ist in der Regel ausreichend

-

Bis 165°C → Es wird eine Barrierefolie aus Aluminium empfohlen

❓ Zusätzliche FAQ basierend auf diesen Informationen

1. Welches Material sollte ich für Hochtemperatur- oder pasteurisierte Produkte wählen??

Wenn Sie heiße Flüssigkeiten einfüllen (bis 165°C) oder eine Vakuumversiegelung erfordern, Wir empfehlen unsere Aluminiumfolienstruktur: PA/AL/PA/PP, das einen hohen Barriereschutz bietet und hoher Hitze standhält.

2. Kann ich LDPE-Liner für chemische oder Lebensmittelanwendungen verwenden??

Ja. Unser klare LDPE-Liner sind sowohl in Standard- als auch in antistatischer Ausführung erhältlich, Dadurch sind sie für Lebensmittelzutaten geeignet, Pulver, oder allgemeine Industriematerialien bei Temperaturen unter 80 °C.

3. Woher weiß ich, welche Linergröße ich benötige??

Stellen Sie einfach Ihre Trommeln bereit Durchmesser und Höhe, oder die Abmessungen Ihres aktuellen Liners. Wir berechnen die richtige Beutelgröße mit entsprechenden Dehnungs- und Passspielräumen.

4. Bieten Sie antistatische Trommelbeutel an??

Ja. Für Anwendungen mit Pulverabfüllung, Elektronik, oder statisch empfindliche Materialien, Wir bieten antistatische LDPE-Rundbodenauskleidung auf Anfrage.