Revolutionize Liquid Packaging with Aseptic Technology

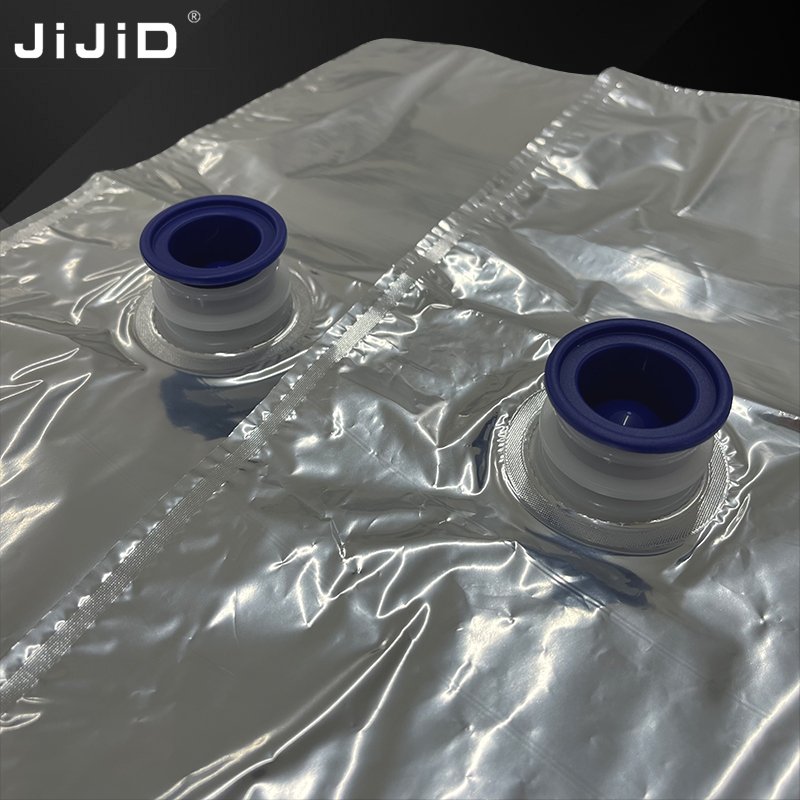

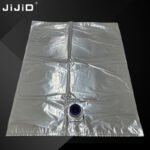

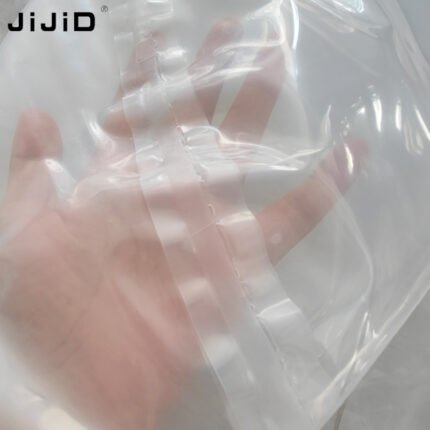

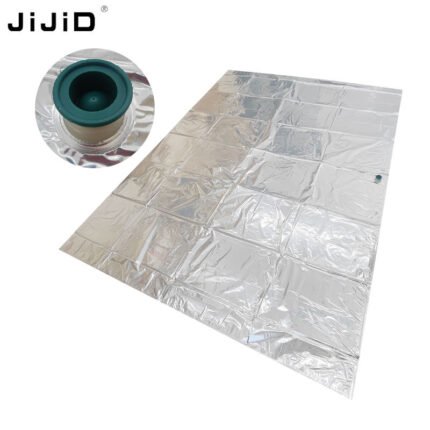

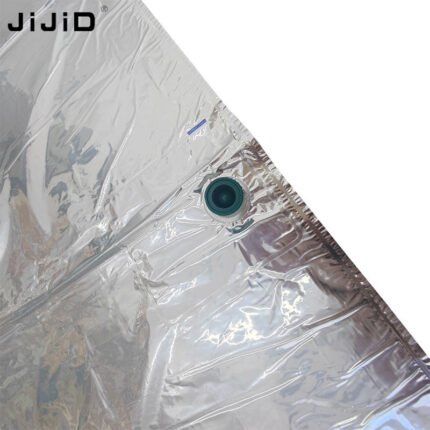

Our premium aluminum foil aseptic bag in box leverages 7-layer co-extrusion technology (PET/AL/PA/PE) to create an impenetrable barrier against oxygen, light, and contaminants. Certified for direct contact with acidic/alkaline foods, this aseptic bag-in-box solution extends shelf life up to 24 months without refrigeration – ideal for global distribution networks.

Core Technical Advantages

- 🚫 Ultra-Low Oxygen Transmission – OTR ≤0.05 cc/m²/day (23°C, 75% RH) preserves delicate flavors in wine and juices

- 🧪 Aseptic Processing Ready – Withstands H₂O₂ sterilization, gamma irradiation, and 121°C hot-filling processes

- 🌑 100% Light Blocking – 7μm aluminum layer prevents UV degradation of photosensitive contents

- 💧 Multi-Layer Safety – PE food-contact layer + PA strength layer + AL barrier = fail-safe protection

Why Choose Our Aseptic Bag in Box?

Compared to traditional packaging, our aseptic bag in box delivers 40% lower logistics costs and 65% less material waste. The collapsible design minimizes storage space after use, while the precision-engineered spouts eliminate drip contamination during dispensing – making this the most efficient aseptic bag-in-box system for liquid manufacturers.

Standard Specifications

| Material Structure | PET (12μm) / AL (7μm) / PA (15μm) / PE (80μm) x2 |

|---|---|

| Volume Options | 1L|3L|5L|10L|20L|220L|1000L|1200L |

| Spout Types | Standard Tap|Eco-Spout|Vent-Spout|Tetra-style Fitment |

| Oxygen Transmission Rate | ≤0.05 cc/m²/day (ASTM D3985) |

| Compliance Certifications | FDA 21 CFR|EU 10/2011|ISO 22000|HACCP|KOSHER |

| Sterilization Methods | H₂O₂|Steam|Gamma Ray|E-beam |

Industry Applications

🍷 Wineries & VineyardsPreserve vintage characteristics with oxygen-free storage. Prevents “bottle shock” during transit.

🧃 Juice & Beverage ProducersMaintain vitamin C content without preservatives. Compatible with high-acid products like citrus and tomato juice.

🥫 Food ProcessingIdeal for edible oils, dressings, and liquid ingredients. Withstands aggressive products like vinegar and soy sauce.

Customization Options

- Printing: 4-8 color flexography with food-safe inks (Pantone matching available)

- Fitments: Tamper-evident caps, EVOH barrier liners, gas-flush valves

- Testing: On-demand migration tests and shelf-life validation studies

“After switching to this aseptic bag in box system, we reduced product returns by 23% and extended our export range to tropical markets.” – Quality Manager, Mediterranean Olive Oil Co.