The 220L Aseptic Bag is a high-barrier, food-grade liner specifically designed to fit standard 200–220 liter drums.

It helps preserve the freshness, flavor, and nutritional value of both liquid and semi-liquid food products.

This bag supports hot or cold sterile filling, eliminates the need for preservatives, and extends shelf life without refrigeration.

As a result, it is widely trusted by food processors and exporters worldwide.

🔍 Ideal for: Tomato paste, fruit puree, juice concentrates, coconut milk, and other liquid foods.

✅ Why Use Aseptic Bags?

Aseptic bags are essential for maintaining product safety during storage and transportation. They provide a sterile, oxygen-free environment, which helps prevent spoilage and microbial contamination.

These bags offer multiple benefits:

-

✅ Lightweight and space-saving

-

✅ Easy to handle, fill, and dispose of

-

✅ Cost-effective for export and bulk operations

-

✅ Compatible with gamma sterilization and CIP/SIP filling systems

In short, they are an efficient solution for modern liquid food logistics.

📏 Product Specifications

| Feature | Description |

|---|---|

| Volume | 220L |

| Bag Size | 940 × 1595 mm |

| Sterilization | Gamma ray (15 KGY) |

| Filling Temperature | -20°C to +95°C |

| Bag Type | Pillow shape / Round-bottom / Form-fit |

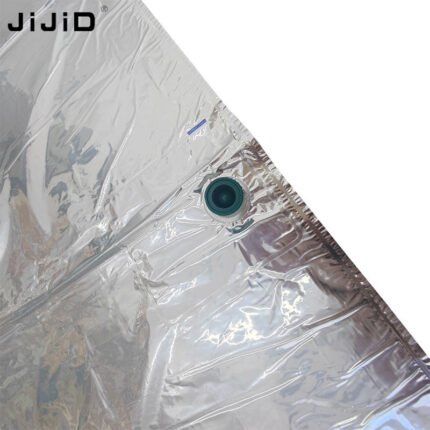

| Valve Options | 1″ ELPO / Butterfly valve / Cap valve (Top or Bottom) |

🧪 Material Options & Structure Comparison

We offer three high-performance materials tailored to different needs. Each has its own unique structure and level of oxygen and light barrier protection:

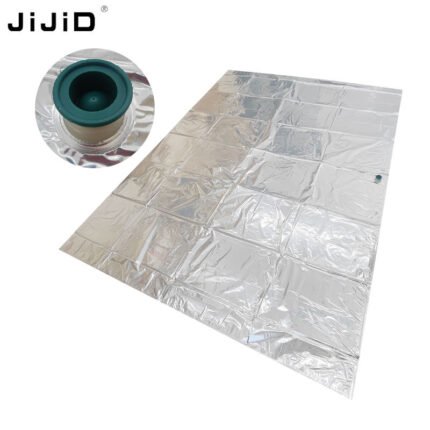

🔸 1. Aluminum Foil Layer

Structure: PE / AL / NY / PE + PE layers

Barrier Performance:

-

Oxygen: ★★★★★ (OTR ≤ 0.1 cc/m²·day)

-

Light: 100% barrier

Applications: Mango puree, banana paste, guava, coconut milk

Best for: Products requiring maximum protection and long-term export storage

🔸 2. Metallic VMPET Layer

Structure: PE / VMPET / PE + PE layers

Barrier Performance:

-

Oxygen: ★★★★☆ (OTR ~1.0 cc/m²·day)

-

Light: Moderate barrier

Applications: Tomato paste, fruit and vegetable concentrates

Best for: Cost-sensitive projects or products with moderate shelf life needs

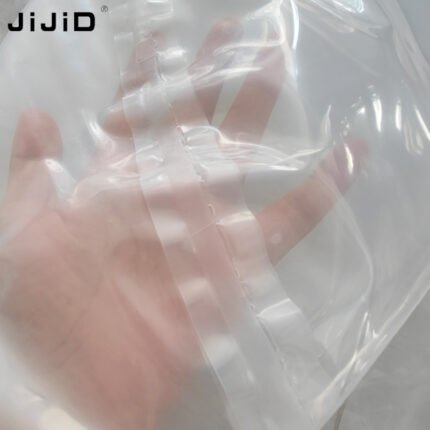

🔸 3. Transparent EVOH Co-extruded Film

Structure: PE / EVOH / PE

Barrier Performance:

-

Oxygen: ★★★★☆ (OTR ~0.5 cc/m²·day)

-

Light: No barrier (fully transparent)

Applications: Coconut water, dairy beverages, nutritional liquids

Best for: Products that benefit from visual transparency or cold-chain delivery

⭐ Key Features

-

✅ Multi-layer, high-barrier construction (8 layers)

-

✅ Leak-proof and puncture-resistant sealing

-

✅ Suitable for hot and cold filling processes

-

✅ Gamma sterilized and ready to use

-

✅ Compatible with all standard drum filling lines

-

✅ Customizable in size, material thickness, and valve type

🌍 Application Industries

Our aseptic bags are widely used in:

-

🧃 Fruit juice and puree processing

-

🍅 Tomato paste production

-

🥥 Coconut-based beverage packaging

-

🥣 Sauce, syrup, and condiment lines

-

🌱 Nutritional supplement and plant extract industries

-

🥛 Dairy and non-dairy liquid food operations

🏆 Why Choose Our 220L Aseptic Bags?

All our bags are manufactured in ISO-certified cleanrooms using advanced German sealing technology.

Furthermore, every production batch undergoes strict quality control to ensure leak-proof integrity and food safety.

Whether you are shipping mango puree across borders or storing tomato concentrate locally, we provide a tailored packaging solution that delivers both performance and peace of mind.

❓ Frequently Asked Questions (FAQ)

Q1: Can I use the same bag for both hot and cold filling?

Yes. Our bags can handle temperatures from -20°C to +95°C, making them suitable for both cold-filled and hot-filled products.

Q2: Which material should I choose—Aluminum, VMPET, or EVOH?

-

Aluminum offers the highest barrier and is ideal for long-term storage and light-sensitive products.

-

VMPET is a more economical option for mid-term storage needs.

-

EVOH is perfect for transparent packaging or chilled products.

Q3: Are the bags sterilized before delivery?

Yes. All bags are gamma-sterilized at 15 KGY and are delivered in a ready-to-use condition.

Q4: Can I customize the size or valve configuration?

Absolutely. We offer flexible customization for bag dimensions, film layers, and valve types or positions.

Q5: Do you offer samples for testing?

Yes. Samples are available upon request so you can test compatibility with your filling process and product.