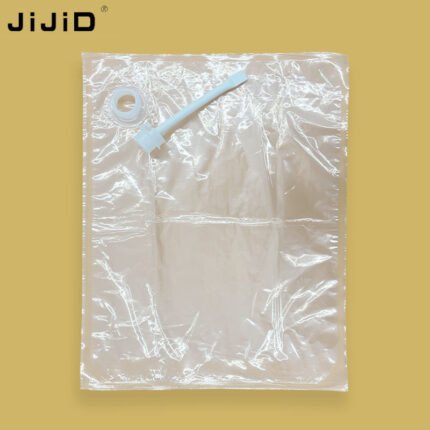

Our Alkali Chemical Packaging Bag is an industrial-grade, chemical-resistant BIB (Bag-in-Box) inner bag engineered for safe storage, transport and dispensing of aggressive liquids — including acids, alkalis, cleaning agents, reagents and selected solvents. Built from a multi-layer laminate specifically selected for chemical compatibility, this chemical safe inner bag for box prevents permeation, protects product integrity and reduces the risk of container failure.

Equipped with a robust water tap valve, the bag provides controlled, drip-free dispensing and is easy to integrate into production lines, labs and field operations. As a trusted reagent storage bag in box supplier option, this solution dramatically lowers handling risk and logistics cost versus rigid drums while improving worker safety and spill control.

Key Features (incorporating target search phrases)

-

Acid resistant bag in box packaging: Laminates and seals chosen to resist common mineral and organic acids.

-

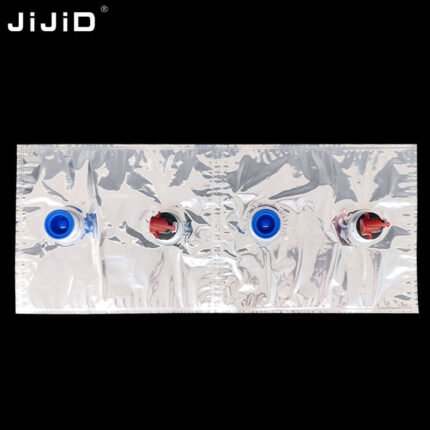

Chemical resistant BIB bag with tap: Durable film and valve assemblies (PP / HDPE / PVDF options) for broad chemical compatibility.

-

Alkali safe bulk liquid packaging: Formulations and thickness options ensure long-term stability with caustic solutions.

-

Solvent resistant BIB container option: Available laminates for selected low-volatility solvents (confirm compatibility).

-

Industrial chemical bag with valve: Threaded water-tap valve for controlled flow and operator safety.

-

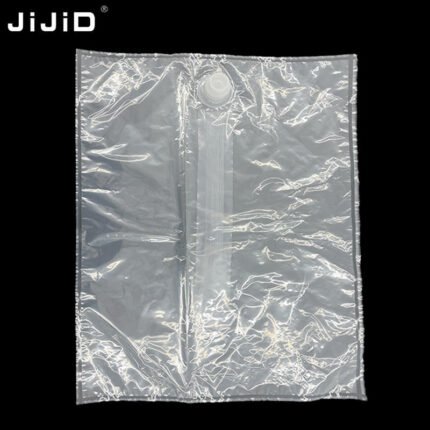

Chemical safe inner bag for box: Heat-sealed seams and tested barrier layers reduce leaks and permeation.

-

Bulk chemical liquid bag packaging: Capacities from 1L up to 220L for lab, industrial and bulk distribution.

Benefits / Advantages

-

Enhanced safety: Lower handling risk compared to open containers and drums; valve reduces operator exposure.

-

Reduced logistics cost: Lighter weight and compact palletization lower shipping and storage expenses.

-

Better chemical protection: Multi-layer barrier reduces vapor loss, contamination and product degradation.

-

Versatile dispensing: Water tap valve fits pumps, funnels and standard fittings for precise dosing.

-

Scalable capacities: From small reagent storage to bulk industrial chemical bag packaging.

-

Customizable: Valve material, film laminate, thickness and outer box printing configurable to your application.

Typical Applications

-

Laboratory bulk reagent storage and dispensing (reagent storage bag in box supplier solutions)

-

Industrial cleaning chemistries, degreasers and detergents

-

Electroplating and surface treatment chemicals (acidic and alkaline baths)

-

Water treatment additives and dosing liquids

-

Agricultural concentrates and sanitizer liquids

-

Selected solvent storage where low volatility and compatibility are confirmed

Technical Specifications (template — customizable per order)

| Item | Typical Options / Notes |

|---|---|

| Core keyword focus | Alkali chemical packaging bag |

| Materials | Multi-layer laminate: combinations of PE / PA / EVOH / Al-metalized layers (chemical-grade blends) |

| Valve | Threaded water tap valve (PP/HDPE/PVDF options); alternative valves available on request |

| Standard capacities | 1L / 3L / 5L / 10L / 20L / 50L / 100L / 220L |

| Film thickness | 0.20–0.60 mm (customizable per chemical compatibility) |

| Chemical resistance | Rated for many acids, alkalis and water-based solvents (compatibility check required) |

| Seals | Heat welded, leak-tested seams |

| OTR / WVTR | Depends on laminate; test reports provided per material selection |

| Temperature range | -20°C to +50°C typical (confirm for your chemical) |

| Outer packaging | Corrugated carton, optional inner fittings or crates |

| Compliance | Material safety & compliance data available; supply SDS or chemical name for exact match |

How to Order / Safety Recommendation

-

Provide the chemical name or SDS (Safety Data Sheet) for compatibility verification.

-

Choose capacity and preferred valve material (PP, HDPE, PVDF).

-

Request sample for compatibility and application testing.

-

We provide lab compatibility guidance and recommended laminate for your specific chemical.

FAQ

Q1: Can this bag hold concentrated acids like sulfuric acid or strong alkalis like sodium hydroxide?

A1: Yes — with the correct laminate and valve material. Please send the SDS so we can recommend an appropriate film/valve combination.

Q2: Is the water tap valve resistant to chemicals?

A2: Valve options include PP, HDPE and PVDF. We will recommend valve material based on your chemical to ensure long-term resistance.

Q3: Can you supply bags for solvents?

A3: We offer solvent resistant BIB container laminates for certain low-volatility solvents. High volatility or UN-classified hazardous solvents require special handling and certification — please consult us with solvent details.

Q4: Are these bags suitable for outdoor storage or palletized shipping?

A4: Yes. Outer corrugated boxes are designed for palletization. For outdoor storage, we recommend additional weather protection depending on storage duration.

Q5: What certifications do you provide?

A5: We provide material declarations and compliance documentation on request. For specific regulatory certifications (REACH, ROHS, food contact, UN), please advise requirements up front.

Q6: How should used bags be disposed of?

A6: Disposal must follow local regulations for chemical containers. Rinse, neutralize or follow your facility procedures; we can advise based on the chemical.