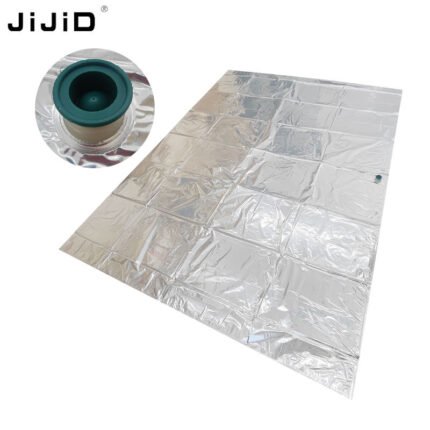

Our 220L Aluminum Foil Aseptic Bag is engineered for superior protection and extended shelf life of liquid food and non-food products. Designed to fit standard 200–220 liter drums, this bag offers a high barrier against oxygen, moisture, and light, ensuring your product stays fresh and safe during storage and transportation.

Key Product Features

-

Material Structure: Multi-layer film combining VMPET, PE, PA, PET, Aluminum Foil, and EVOH, providing excellent barrier properties.

-

Application: Suitable for both liquid food (juices, purees, sauces) and liquid non-food products.

-

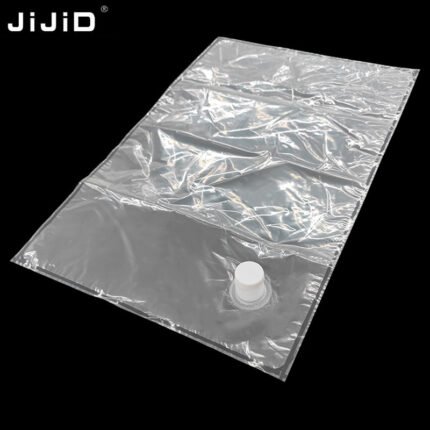

Capacity: Available in 200L or 220L sizes to fit standard drums.

-

Barrier Options: Offers standard, high, and ultra-high barrier levels tailored to your product’s shelf life requirements.

-

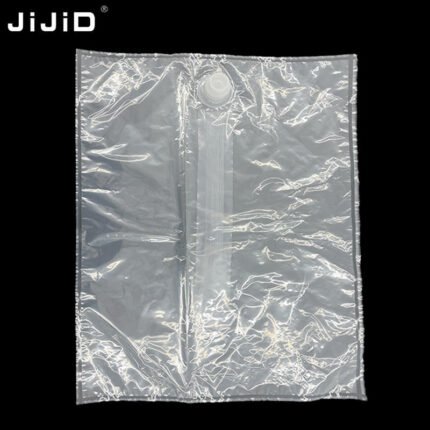

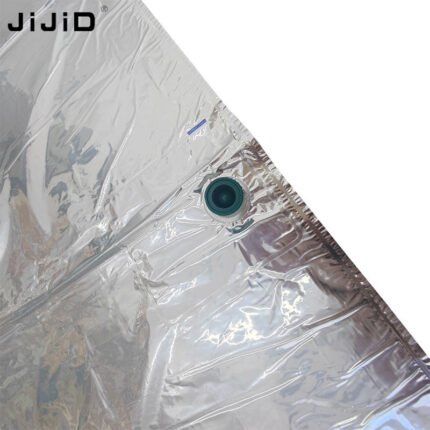

Bag Type: Equipped with a convenient spout for easy filling and dispensing.

-

Sterilization: Gamma irradiation sterilization with ≥15kGy dose to ensure aseptic conditions.

-

Lamination Process: Uses solvent-free lamination technology to enhance safety and environmental friendliness.

-

Film Advantages: Top flex crack resistance, ensuring durability and integrity during handling and transportation.

-

Compliance: Meets ABMA and European food safety standards, guaranteeing product safety and quality.

Why Choose Our Aluminum Foil Aseptic Bags?

-

Superior Oxygen and Moisture Barrier: The aluminum foil layer effectively blocks light and oxygen, significantly reducing product oxidation and spoilage.

-

Sterile and Safe: The bags are sterilized via gamma irradiation, ensuring aseptic conditions ideal for long shelf-life products without refrigeration.

-

Durability: Resistant to cracking and punctures, maintaining integrity throughout transport and storage.

-

Environmentally Friendly: Manufactured with solvent-free lamination, minimizing environmental impact and ensuring food-grade safety.

-

Versatile Use: Perfect for aseptic packaging of juices, purees, sauces, plant extracts, and liquid chemicals requiring sterile conditions.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Structure | VMPET / PE / PA / PET / Aluminum Foil / EVOH (multi-layer) |

| Product Size | 200L / 220L |

| Barrier Level | Standard / High / Ultra-High Barrier |

| Bag Type | Bag with Spout |

| Feature | High Barrier, Aseptic |

| Standard Compliance | ABMA Standards (European Standards) |

| Sterilization Method | Gamma Irradiation (≥15 kGy) |

| Lamination Process | Solvent-free Lamination |

| Film Advantages | High Flex Crack Resistance |

| Raw Materials | Food Grade, Safe for Consumption |

❓ FAQ Section

Q1: Can these bags be used for gamma or steam sterilization?

A1: Yes, our pure aluminum foil bags are compatible with gamma irradiation, autoclave steam, and ETO sterilization processes.

Q2: Can I order custom dimensions or add a valve spout?

A2: Absolutely. We support OEM customization for size, valve location, and even multi-layer composite materials.

Q3: What’s the lead time for bulk orders?

A3: Standard lead time is 12–15 working days. For custom orders or large quantities, we’ll confirm the schedule upon order confirmation.

Q4: Which material should I choose—Aluminum, VMPET, or EVOH?

-

Aluminum offers the highest barrier and is ideal for long-term storage and light-sensitive products.

-

VMPET is a more economical option for mid-term storage needs.

-

EVOH is perfect for transparent packaging or chilled products.

Q5: Do you offer samples for testing?

Yes. Samples are available upon request so you can test compatibility with your filling process and product.